Tyvek® Products

Medical Grade Tyvek® Products

Packaging made of DuPont Tyvek® and medical grade easy peel PE film which is suitable for all light to medium or heavy instruments or bulky material which requires low temperature sterilization. The product provides extremely high penetration resistance packaging.

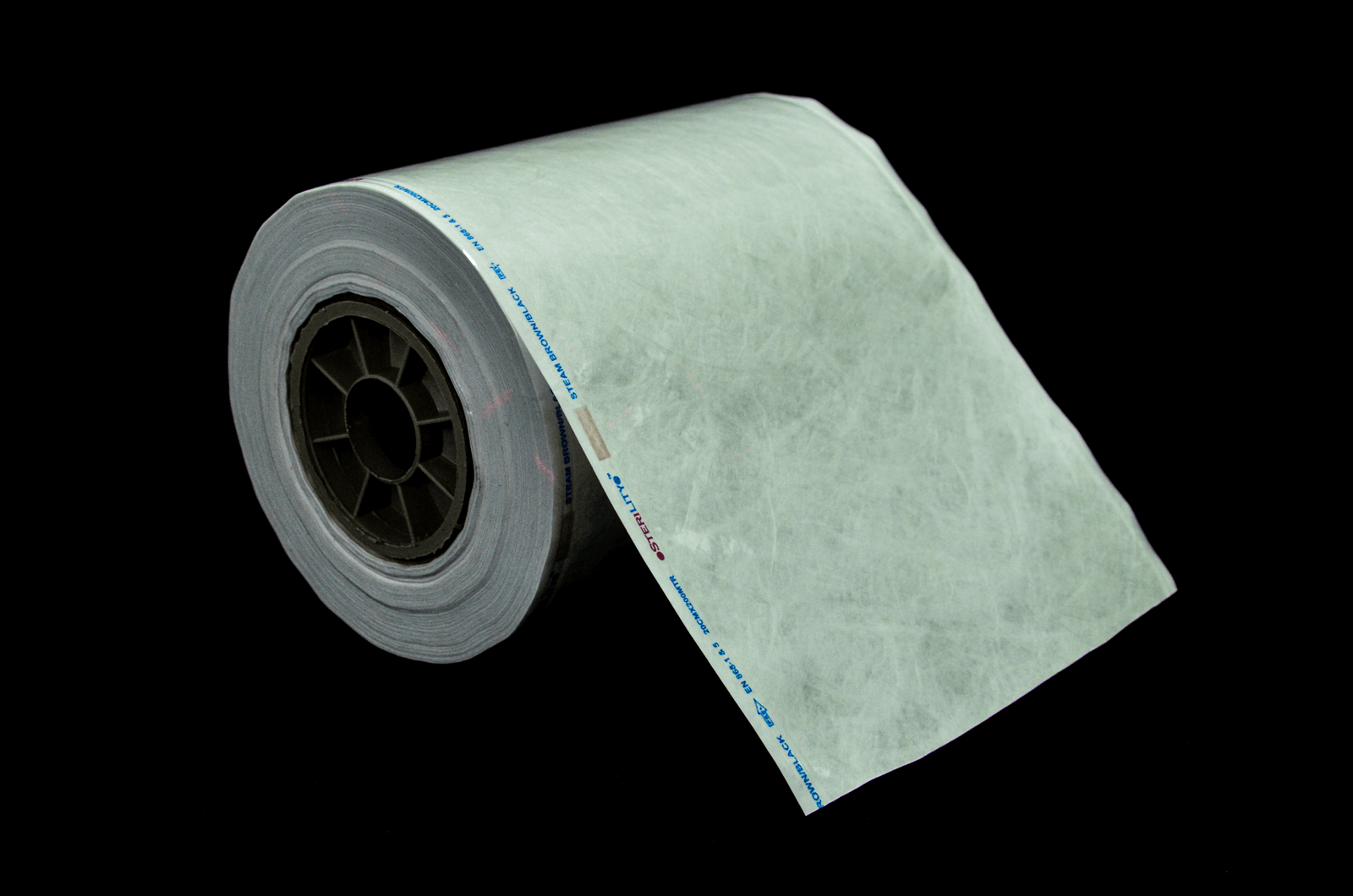

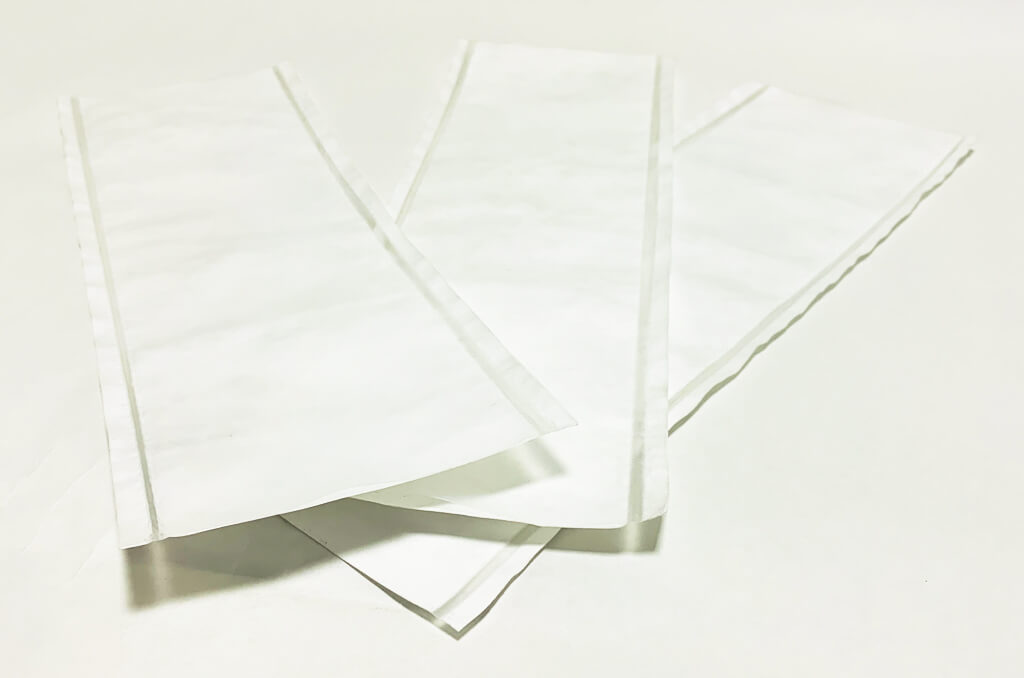

STERILIZATION TYVEK® REELS & POUCHES

Available Sizes

| 5 cm x 200 mtr | 7.5 cm x 200 mtr | 10cm x 200 mtr |

| 12.5 cm x 200 mtr | 15 cm x 200 mtr | 20 cm x 200 mtr |

| 25 cm x 200 mtr | 30 cm x 200 mtr | 35 cm x 200 mtr |

| 38 cm x 200 mtr | 40 cm x 200 mtr | 42 cm x 200 mtr |

| 45 cm x 200 mtr | 50 cm x 200 mtr | 60 cm x 200 mtr |

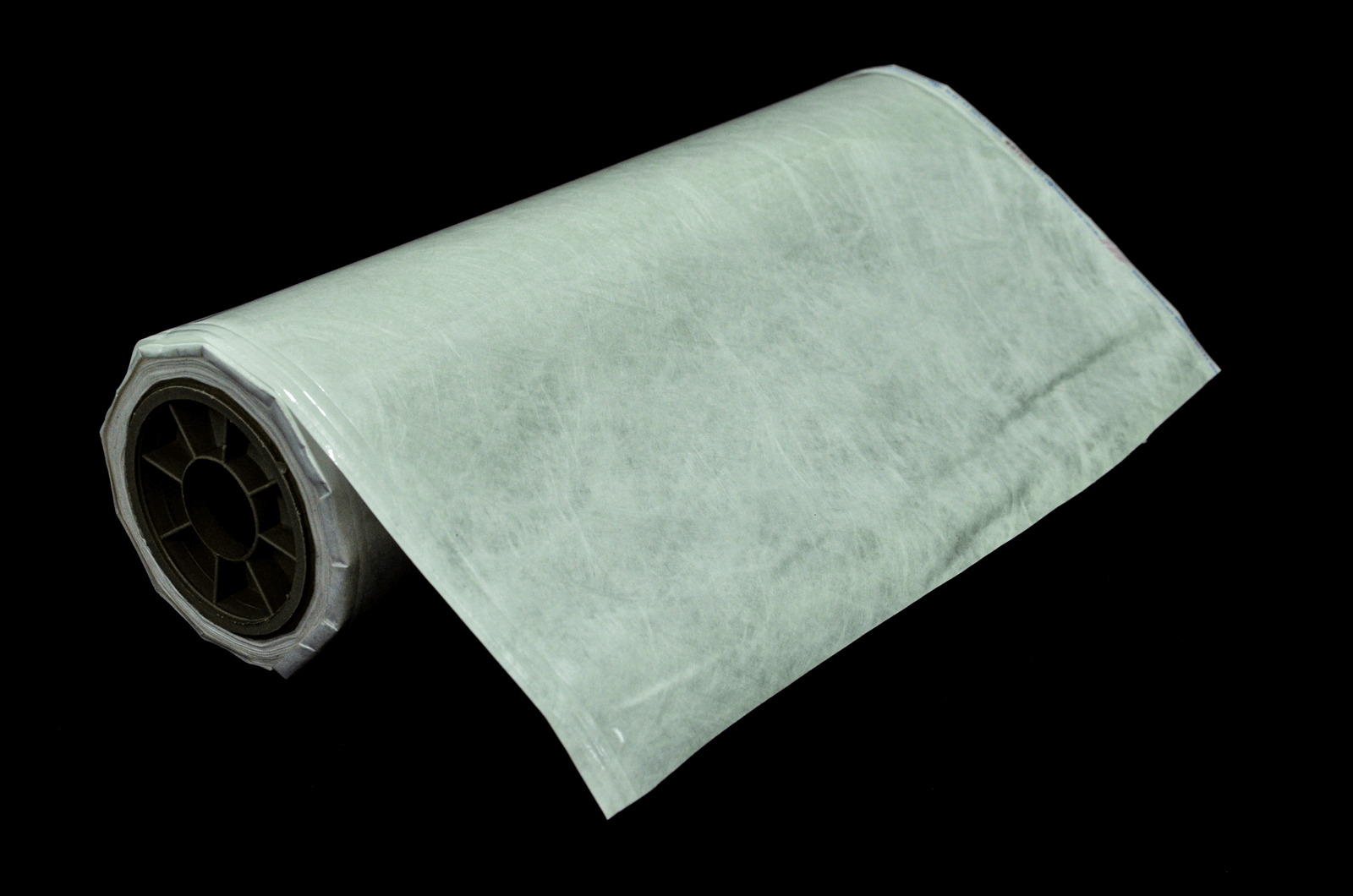

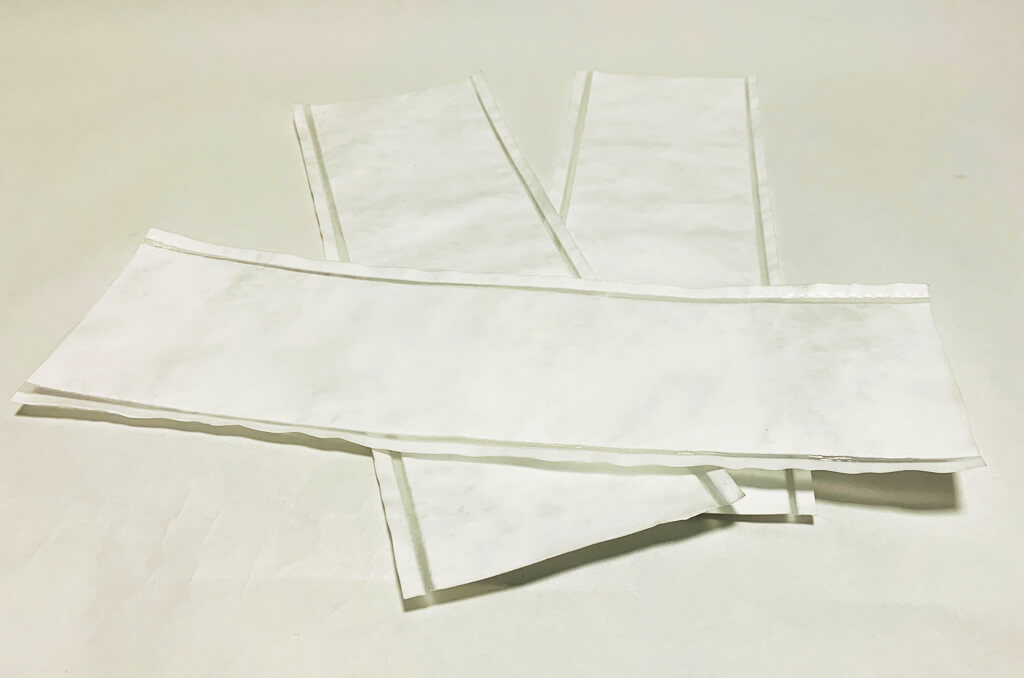

STERILIZATION TYVEK® GUSSETED REELS & POUCHES

Available Sizes

| 7.5 cm x 200 mtr | 10 cm x 200 mtr | 12.5 cm x 200 mtr |

| 15 cm x 200 mtr | 20 cm x 200 mtr | 25 cm x 200 mtr |

| 30 cm x 200 mtr | 35 cm x 200 mtr | 38 cm x 200 mtr |

| 40 cm x 200 mtr | 42 cm x 200 mtr | 45 cm x 200 mtr |

| 50 cm x 200 mtr |

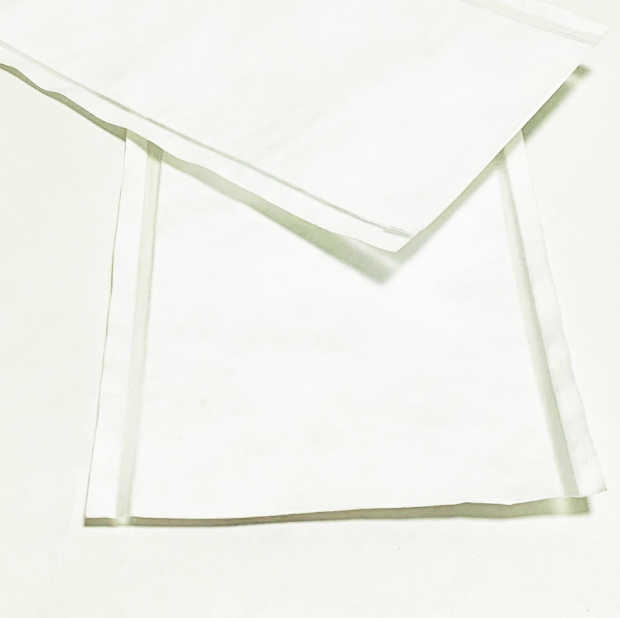

STERILIZATION SELF SEAL TYVEK® POUCHES

Available Sizes

| 5 cm x 27.5 cm | 7.5 cm x 27.5 cm | 10 cm x 27.5 cm |

| 15 cm x 27.5 mm | 20 cm x 27.5 cm | 25 cm x 40 cm |

| 30 cm x 50 cm | 35 cm x 50 cm | 40 cm x 50 cm |

| 45 cm x 50 cm | 50 cm cm x 60 cm |

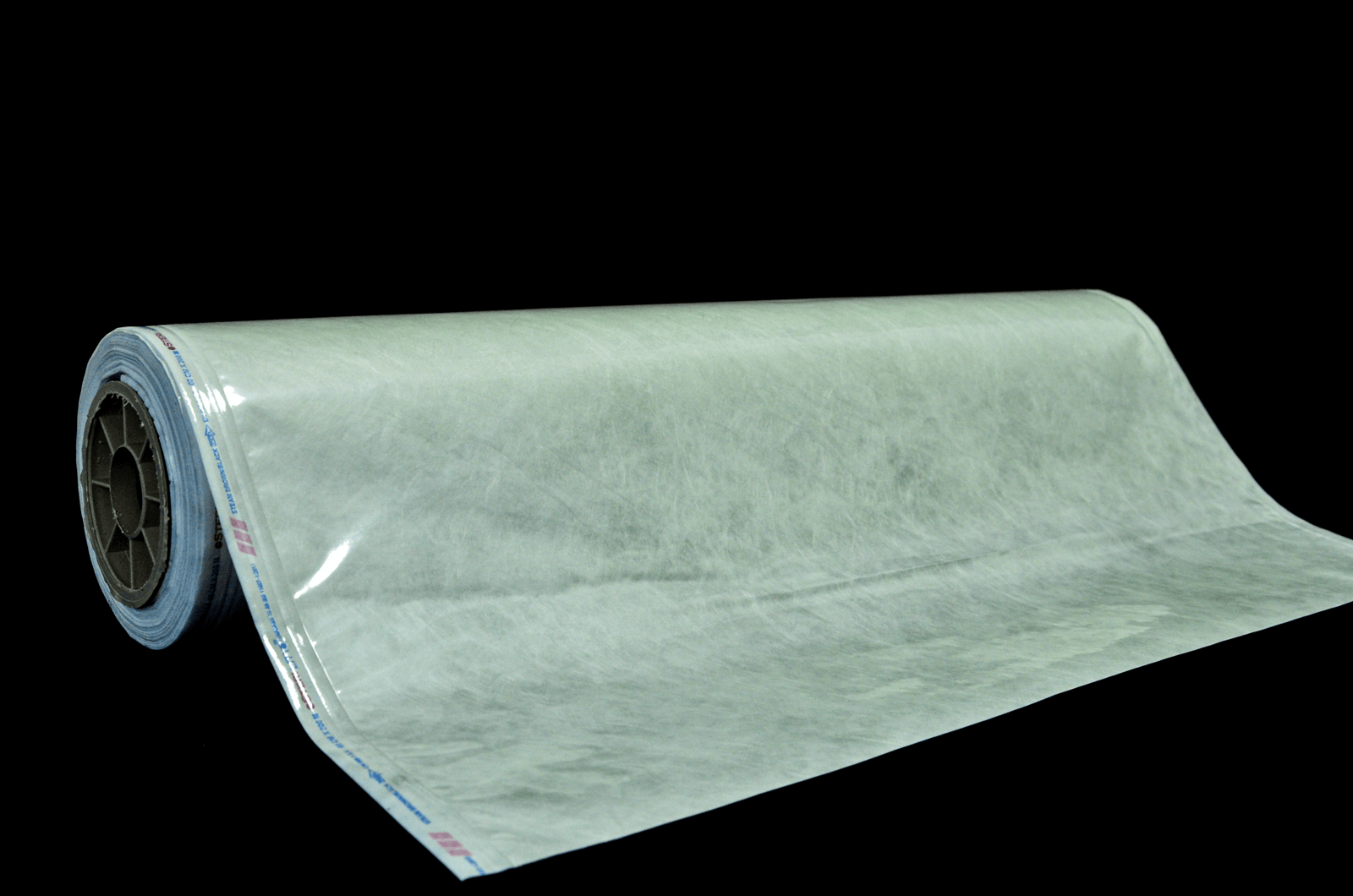

Tyvek® HDPE Reels/ Pouches

These reels are pouches are made from Medical Grade (1073B) DuPont™ Tyvek® and HDPE Film. The Tyvek® side provides superior microbial barrier characteristics, while the HDPE film side offers contact clarity.

Originally designed for the steam sterilization of pharmaceutical components, such as stoppers and overseas, these bags are also useful with heavier equipment change parts. The bags are designed to be heat-sealed closed.

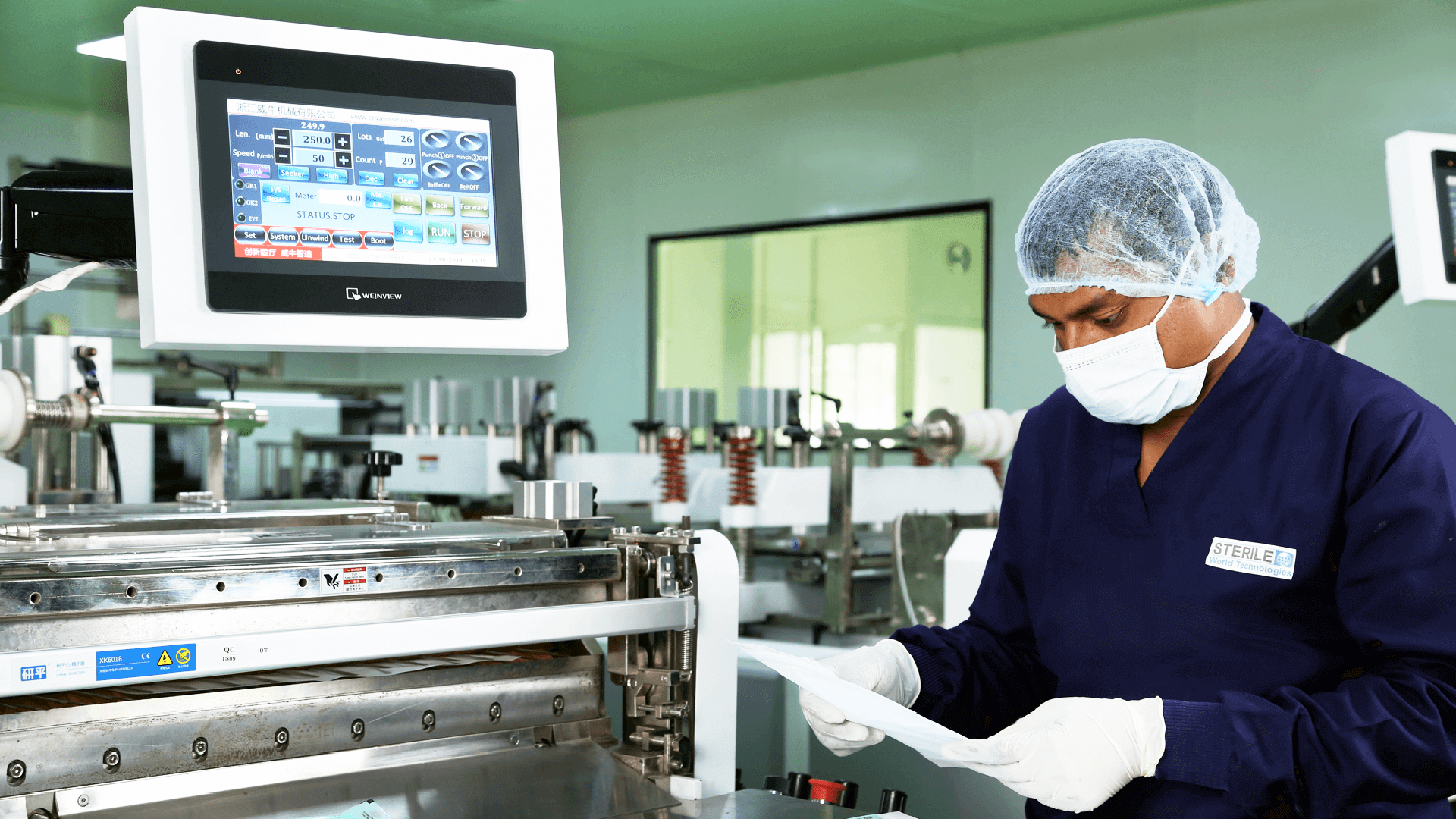

- Manufactured and packaged in a controlled cleanroom environment

- Steam sterilization indicator – autoclavable at 121 to 134 °C

- Tear and puncture-resistant

- Hydrophobic and lint-free

- Excellent impact resistance with exceptional microbial barrier

- Consistently strong, double-welded factory seals

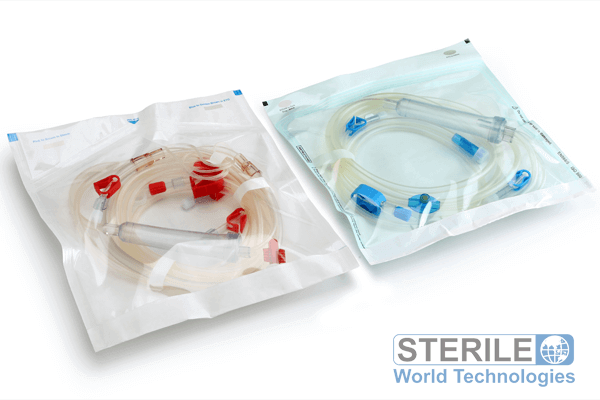

TYVEK® Header Bags

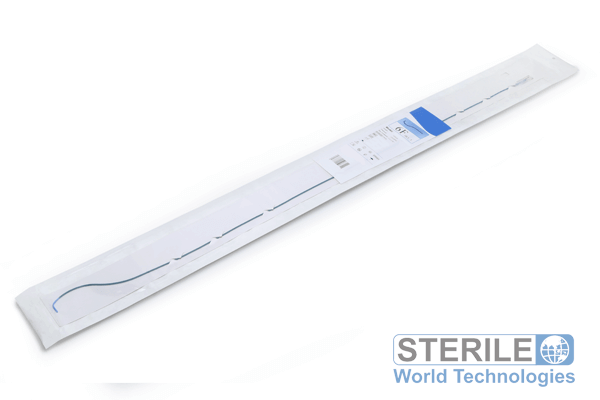

Some of our medical devices and procedure kits requires to be packaged in film-film packages or foil pouches because they require a barrier to light, oxygen and/or moisture. As they need to be sterilized with EO which is not possible in non-breathable material like film and foil so presenting a header bag with a breather patch made of a porous packaging material such as Tyvek®.

Header bags made with Tyvek® enable EO sterilization of medical devices within film-film packages and foil pouches because Tyvek® allows the moisture and heat from EO sterilization to pass in—and out—of the package.

In addition to enabling EO sterilization, headers made with Tyvek® have superior puncture resistance compared to headers made with medical-grade paper. Header bags made with Tyvek® also offer superior moisture resistance and microbial barrier compared to those made with medical-grade papers.

We can manufacture variable sizes as per the customer’s particular requirement and specifications on printing and sizes.

Applications

- For Clean room garments and /or gown/ gown kits

- For Bulky Devices

- As Second barrier for trays

- For various Kits and surgical trays

- For Tubing sets and/ or catheters

- For some critical medical devices

TYVEK® Bowl Cover

These bowl cover is the ideal choice in pharmaceutical operations to help keep clean equipment protected from both environmental and product cross-contamination. These are Autoclavable Bowl Covers prevent microbial and particulate contamination also.

Features -

- Keeps cleaned equipment clean and protected from contamination

- Breathable

- Form-fitting, fast and consistent

- Conveniently packaged: 1 heat-sealed labeled polybag

- Reduces labor costs

- Simplifies the conformance to wrapping SOP’s

- Steam Sterilization Indicator – Autoclavable at 121°C-125°C

- Tear and puncture-resistant

- Lint-free

Packaging Features

The packaging correspond to the requirements of DIN EN ISO 11607 and EN 868-2.

Manufactured using of medical DuPontTM Tyvek®: Type 1073 B (Uncoated) and 2FS (Uncoated).

- It provides excellent barrier properties against germs and moisture

- It is extremely high penetration resistance

- Offers easy and fibre-free peel

- Can be designed by implementation of customer-specific layouts

- Printing of labels & indicators can be done according to the customer's requirements

- Products can be customized as per special sizes and special formats

- Special lengths up to 1,500 mm on inquiry are available

STERILIZATION METHODS

- STEAM

- FORMALDEHYDE

- IRRADIATION (GAMMA / E-BEAM ETC.)

- VH202 (PLASMA)

- ETHYLENE OXIDE

Customer Benefits

The packaging can maintains the sterility up to 180 days*

Tyvek® web provides excellent strength and microbial barrier qualities

Permeable Tyvek® web allows efficient packing of sealed pouches

Allover coated Tyvek® provides excellent peelability

.png)